Check out what's going on in your immediate vicinity. Your current physical location. That stuff you write on. The car you use to go around. From the carpet you walk on to the chair you sit in, the flock has worked its way into every aspect of modern life.

It's remarkable how flocking can be used to give almost any material a silky, velvety, or brush-like finish. T-shirts, perfume bottles, car glove boxes, car headliners, floor coverings, model train scenery, eyeliner brushes, scouring pads, and so much more are just some of the many products that feature flocked designs.

Buyers are always on the lookout for something special. All of the industry's suppliers are on the lookout for the same thing: a game-changing innovation that will expand their customer base and increase sales. Making something new and interesting is always a top goal, and this is what has sparked printers' renewed interest in flocking.

Flock screen printing: what is it, exactly?

Flock Screen printing, also known as flocking, is the method of adding dye, adhesive, and countless tiny fiber particles (called flock) to the surface of a t-shirt or garment. Flock can be made from either natural or synthetic materials like cotton, rayon, nylon, or polyester.

It's a great way to enhance a garment's touch, color, and overall appeal by giving it a velour, fluffy, velvety texture. Adding flocking to your clothing line is a certain way to make it stand out from the competition.

Fashions and Developments in Flock Printing

Some historians believe that the practice stretches back thousands of years to when fibers were brushed across a simple adhesive to change the feel of a garment. The screen printing font Flock made its debut in the middle of the twentieth century in the United States and has remained popular ever since.

In an effort to stand out from the crowd and create a more professional appearance than the traditional screen printing process, local sports teams have begun inserting these minuscule threads into the numbers on their uniforms.

Compared to traditional screen printing techniques, flock printing ensured that the design stood out and was more tactile to the touch. Thus, this technique provided the first significant novelty for screen-printed clothing.

Flock printing is equally adaptable in terms of the substrates it can be applied on. Toys, paper patterns, plastic, and other items are all fair game for this method. This aesthetic lingered for decades and found its way into fields as diverse as fine art and greeting card design.

Even car manufacturers employ flock to muffle noise within the cabin. This flexible method can be used in place of an existing liner or in any other location where a specially tailored fabric is required. Adding texture to a wide range of tools and equipment can lessen the need for constant rubbing and sliding, as well as increase user comfort.

This method is still employed on many modern sports and leisure shirts due to its ability to make a colorful emblem or number pop off the fabric. During production, the flock is bonded so strongly that the finished product can resist significant wear and tear in the workplace or on the field.

How Does Flock Printing Work?

There is more to flocking than simply adhering microfibers to an adhesive-flocked surface. Basically, there are four distinct methods used to generate this look, with some being much more scientific than others. Which method is ideal depends on the number of colors in the design, the output capacity of the wholesale screen printing manufacturer, and the final product's intended use.

All flock printing involves a similar series of steps, including making a stencil, applying adhesive to the material, adding the flock, curing/drying, and removing any excess. Any flock that doesn't adhere to the stencil can be manually removed using a blow dryer or a vacuum.

Stenciling Flocking

If you're working with difficult textiles like terry cloth or oddly shaped products, transfer flocking is a terrific way to save time and money. The flock can adhere to a thermal backer, which can then be digitally cut to the exact stencil in the file. Do you know that heated pressure is used to bond the flock and back to the substrate?

Several fashion houses have begun using the technique in place of embroidery and conventional flocking on difficult projects due to its versatility and suede-like appearance. The adaptability that comes with a flock stencil makes it ideal for adding logos to high-wear items like sports or school uniforms.

Manual Flocking

Manual flocking, also known as direct flocking, is the most interesting method and may be performed by experienced screen printers with the right equipment. The method involves a machine that applies adhesive ink on the item's outline of the design.

Next, it goes into a flocking machine, where an electric charge helps further the process. Negatively charged flock fibers go through the air and are picked up by a grounded reception material like a t-shirt or a plastic car dashboard. To provide a neat, fabric-like look, the flock is charged in the opposite direction from the adhesive, so it stands upright when it lands on it. Think about the instant when static electricity makes your hair stand on end. Since the fibers are all running in the same direction, the flock does not bunch up or lie on its side.

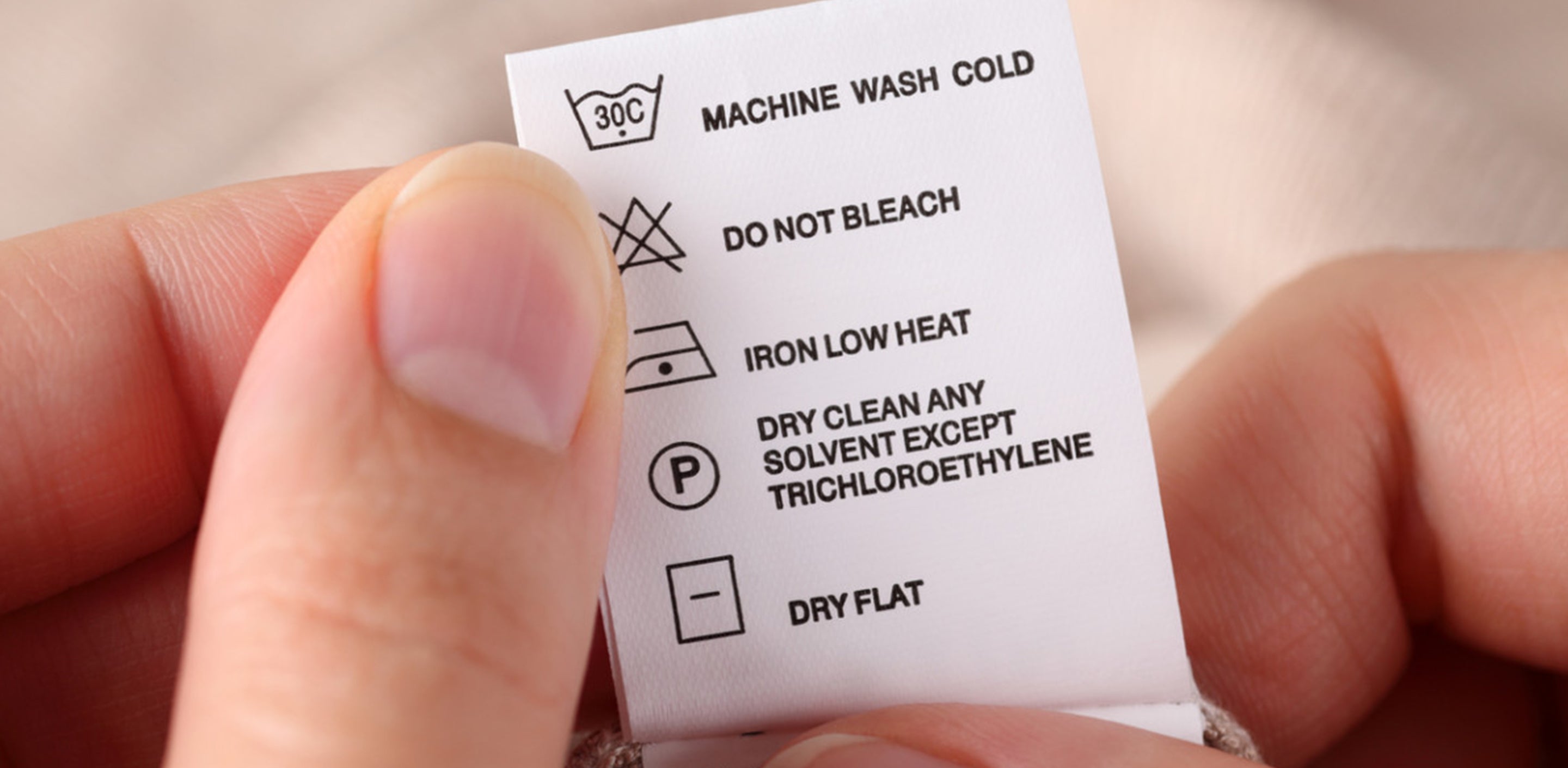

Depending on the material, glue can be cured at higher temperatures than regular ink. The method's durability increases with the adhesive strength, thus washing and dry cleaning are options.

Compressed Air Flocking

One of the simplest and fastest ways to apply flock is with a compressed air flocker. Flock is applied in a steady stream with the help of a flocking gun or machine and some pre-laid glue. Similar to hand flocking, unwanted flocks can be removed by blowing them away or vacuuming them up.

Transfer Flocking

First, an adhesive ink is applied to the material in the form of the design, just like in conventional screen printing. Once the ink has cured and dried, the design is set in. Then, the appropriate-colored flock transfer paper is laid on the ink and heated to transfer the flock to the inked pattern. As the transfer is removed by the designers, only the flock sitting on the glue is visible.

FAQ

What is flock used for in the textile industry?

Flock is used for bonding fine and very short polyamide strands, giving the fabric a suede look. Tannic acids, in conjunction with aluminum salts, are commonly utilized for the electrostatic activation of nylon fibers.

What is a flock design?

Flock prints are those in which small lengths of fiber known as "flocks" stand erect on the cloth surface to make a design. "Flocking" refers to the technique of gluing minute fragments of the flock to fabric to make a design.

We also happen to be a magnet for suggestions, and would love to catch yours….throw us yours on hello@fabriclore.com