Importance of Textile Testing

- Quality control: Textile testing helps to ensure that products meet the desired quality standards. It allows manufacturers to identify any defects or issues early on in the production process, which can be corrected before the product is released into the market.

- Compliance with regulations: Many countries have regulations in place to ensure that textile products are safe for consumers. Textile testing helps manufacturers to ensure that their products meet these regulations and are safe for use.

- Product development: Textile testing can be used to evaluate new materials and designs. It allows Fabric manufacturers to test the performance of different materials and determine which ones are most suitable for their products.

- Marketing: Textile testing can also be used as a marketing tool. Testing results can be used to promote the quality and safety of products to customers.

Methods and Techniques for Textile Testing

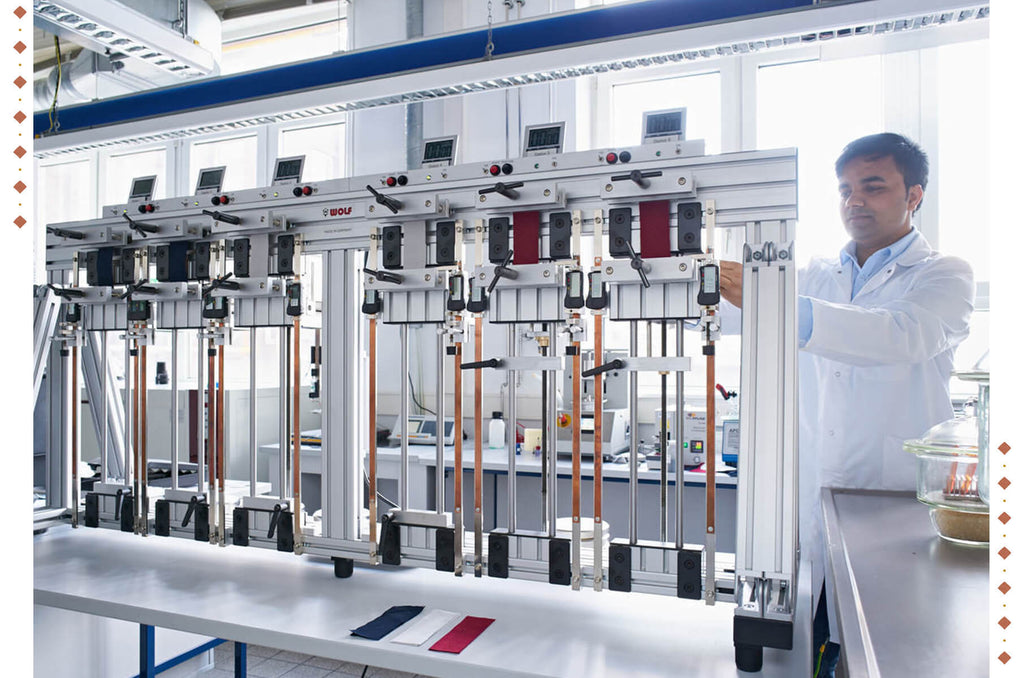

- Physical testing: This involves evaluating the physical properties of textiles, such as strength, elasticity, and abrasion resistance. Physical testing can be performed using a range of methods, including tensile testing, tear testing, and pilling resistance testing.

- Chemical testing: This involves analyzing the chemical properties of textiles, such as pH, color fastness, and fiber content. Chemical testing can be performed using a range of techniques, including spectrophotometry, chromatography, and titration.

- Flammability testing: This involves evaluating the ability of textiles to resist burning. Flammability testing can be performed using methods such as the vertical flame test, horizontal flame test, and oxygen index test.

- Microscopic testing: This involves examining textiles under a microscope to identify the fiber type, weave structure, and other physical characteristics.

- Durability testing: This involves evaluating the ability of textiles to withstand wear and tear. Durability testing can be performed using methods such as the Martindale abrasion test, Wyzenbeek abrasion test, and flex testing.

In conclusion, textile testing is an important step in the manufacturing process that helps to ensure product quality, safety, and compliance with regulations. There are several methods and techniques available for textile testing, and manufacturers should select the most appropriate ones based on the specific properties they need to evaluate.

FAQ

How can textile testing help ensure product quality?

Textile testing is an ideal method for detecting manufacturing and material defects. The demand for high-quality textiles and clothing is on the rise, and with that comes the need for testing to guarantee that products are safe and in line with ever-evolving government safety laws.

What is involved in textile quality control?

Several components of textile manufacturing and the finished garment are used as yardsticks for evaluating quality control. Choosing which materials to use. Manufacture of fibers. Creation of yarn.

We also happen to be a magnet for suggestions, and would love to catch yours….throw us yours on hello@fabriclore.com